How To Make The Right Choice?

To choose the right shoe, you need to take account of a number of different parameters:

- The work environment (indoors or outdoors)

- The specific conditions (heat, cold, clean or dirty floors, type of terrain)

- The risks the wearer is exposed to (crushing, slipping, electrocution, etc.)

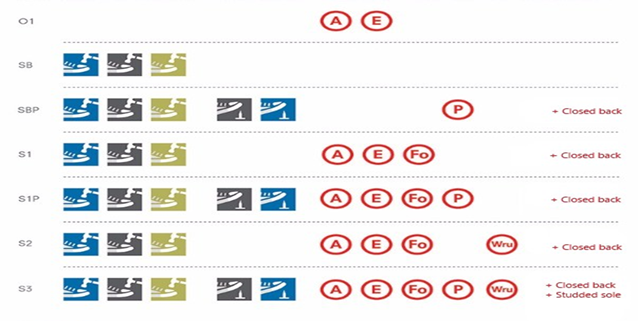

The table below provides all the details needed to choose your work shoes. Start by evaluating the risks you face in your workplace to select the level of protection you need

Protective Toecaps

The toecaps that are certified to European standards protect you against impacts of 200 Joules, which is equivalent to a 20 kg load falling from a height of one metre, and against crushing with a force equivalent to 1500 kg.

There are 4 types of protective toecaps, depending on their composition:

- Aluminium toecaps, thin and very lightweight

- Stainless steel toecaps, thin and relatively wide to guarantee comfortable movement

- Polycarbonate toecaps, offering a high level of heat resistance, lightweight and non-magnetic They do not set off the alarm on security gate scanners

- Composite fibre toecaps, insulating against heat and cold and also non-magnetic

Steel

Wide toecap for greater comfort

Polycarbonate

Ultra-light, non-magnetic, thermal insulation

Aluminium

Wide, very lightweight toecap

Fibre

Non-metallic, non-magnetic, non-conducting of heat and cold.

Note

In the event of a substantial impact on your foot, your safety shoes will need to be changed. The impact may have damaged the protective toecap, you are no longer protected 100%.

Placing a shop-bought insole inside the shoe reduces the space available for your toes inside the protective toecap, you are no longer as well protected against the risk of crushing and anti-static risks.

Anti-perforation Inserts

The use of pierce resistant midsoles protects you when you step on a blunt or sharp object on your work site, Standard ISO 20345 determines the level of resistance necessary to protect you against mechanical puncture risks. A pierce-resistant midsole can resist a static penetration force of 1100 Newton, which is equivalent to the force generated by an 80 kg person walking and placing their foot on a nail with a blunt tip 4.5 mm in diameter.

Two types of midsoles are used for personal protective equipment:

1. Midsoles made of high tenacity composite fabric: these have the advantage of being flexible and lightweight. As they are non-metallic, they are non-magnetic. Composite fabric is a material known for its thermal insulation powers; it does not conduct heat and cold. It covers 100% of the surface of the foot as it is sewn in when the upper is assembled.

2. Stainless steel midsoles: these are stronger, but less flexible.

The main hazards which may need foot protection are:

- Objects falling on and crushing the foot/toes – this will include jobs requiring manual handling, such as construction workers or removal people.

- Treading on pointed or sharp objects (eg nails) on the ground piercing the shoe, injuring the sole of the foot and resulting in cuts and wounds;

- Slips, trips and falls resulting in injuries such as sprained ankles. Although there is no such thing as non-slip footwear, there are slip-resistant ‘anti-slip’ soles which can reduce the likelihood of slipping on certain floors;

- Working in cold or hot conditions. Working in the cold requires footwear with thermal insulation. Work in hot conditions requires footwear with heat-resistant and insulating soles. For protection against molten metal splash, footwear must have quick release fastenings;

- Electrical hazards (see paragraph 97(c) for further information);

- Working in potentially explosive atmospheres or for the handling of sensitive materials (eg detonators). Footwear must be antistatic;

- Working with and handling hazardous chemicals. Footwear should be impermeable and resistant to that chemical;

- Wet work, for example using water sprays when cleaning. Water-resistant or waterproof material should be used. Wellington boot style footwear should be used for very wet work.

Key points to note about protective footwear:

- Consider the comfort factors for the wearer. Generally, footwear should be flexible, wet resistant and absorb perspiration. Cushioned soles make standing more comfortable;

- Inspect for wear and tear and loose seams before use. Replace broken laces and remove materials lodged in the tread of the sole.